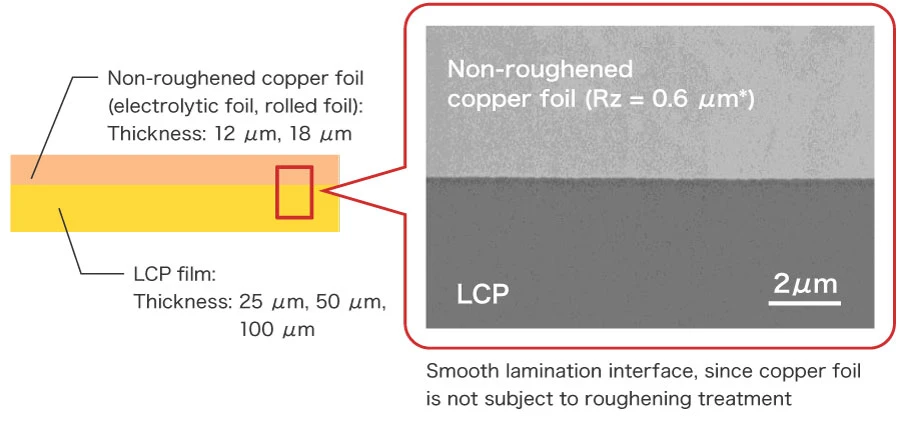

LCP base (for subtractive processes)

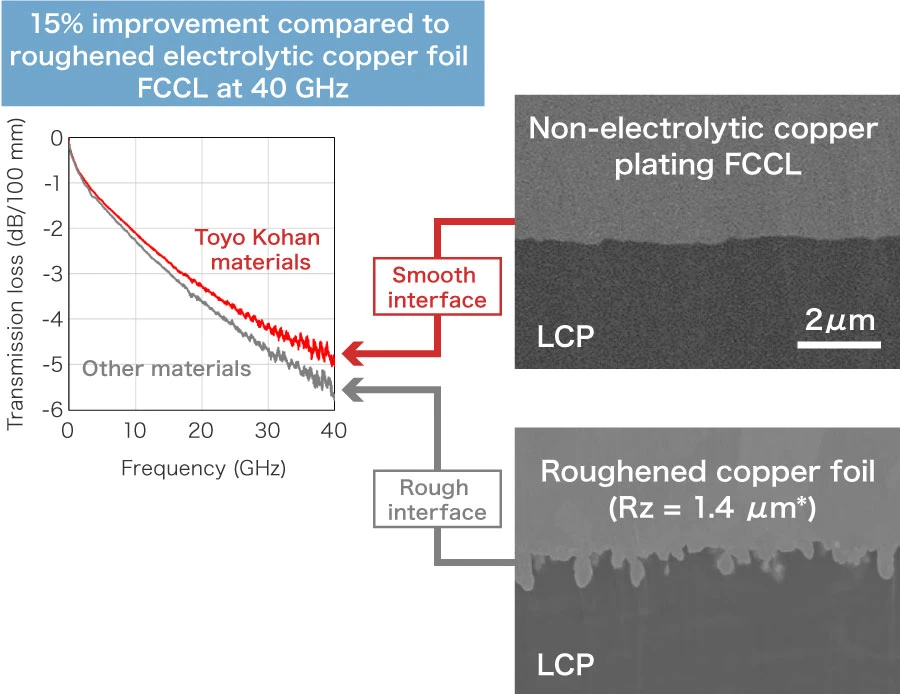

Laminated with non-roughened copper foil and LCP film, FCCL offer smooth interfacing and excellent high-frequency characteristics

- Provided width: Max. 510 mm

- Format: Rolls, sheets

Composition

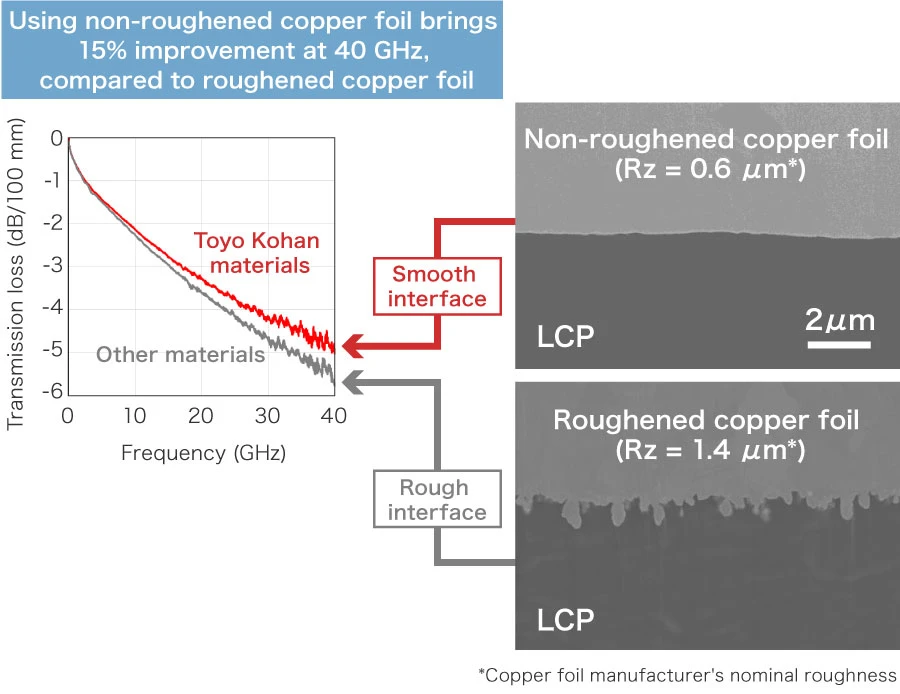

Low transmission loss

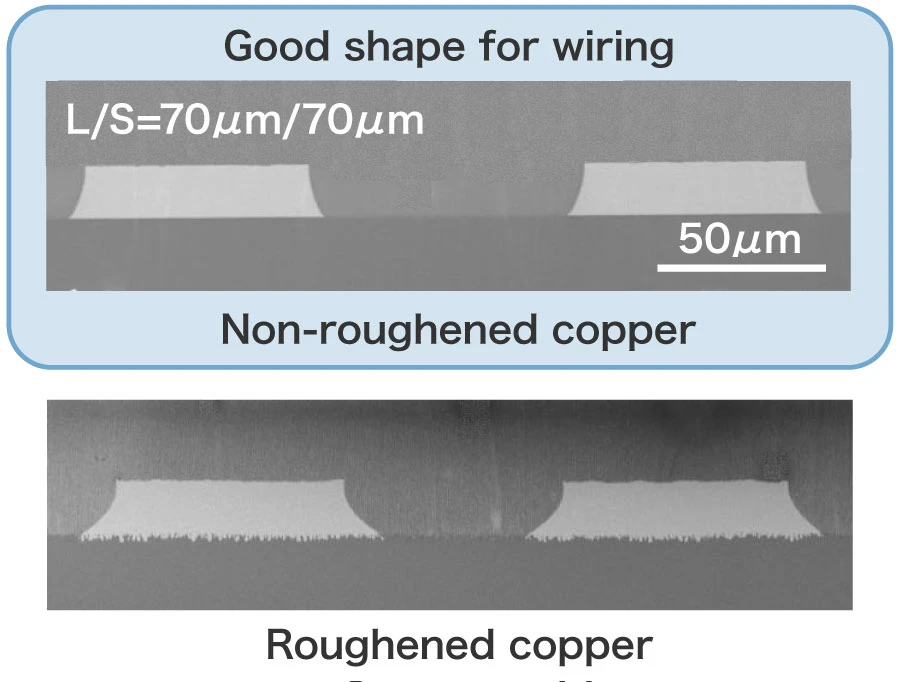

Achieving good shape for wiring using subtractive method

General properties

| Item | Conditions | Non-roughened copper foil FCCL |

|---|---|---|

| Conductor peel strength (N/mm) | 18 µm rolled copper foil at room temperature | 0.6 |

| Elongation | 38% | 13% |

| Dielectric dissipation factor | Open resonant Fabry–Perot method 28GHz | 0.002 |

| Relative dielectric constant | 3.3 | |

| Solder heat resistance | 288°C, 10 seconds | No abnormality |

The above data are representative values measured by our company, not guaranteed values

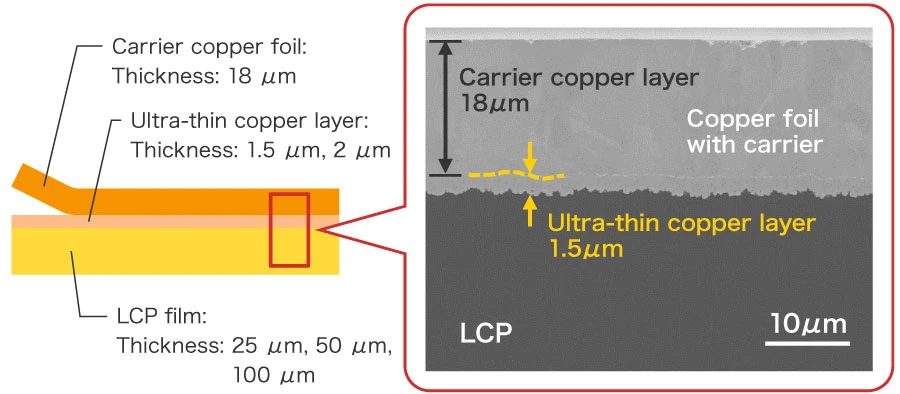

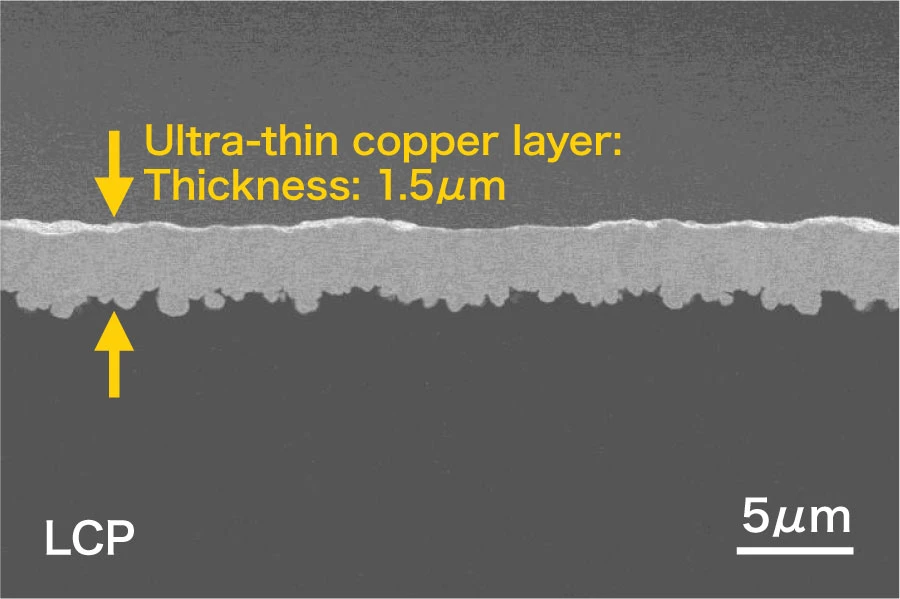

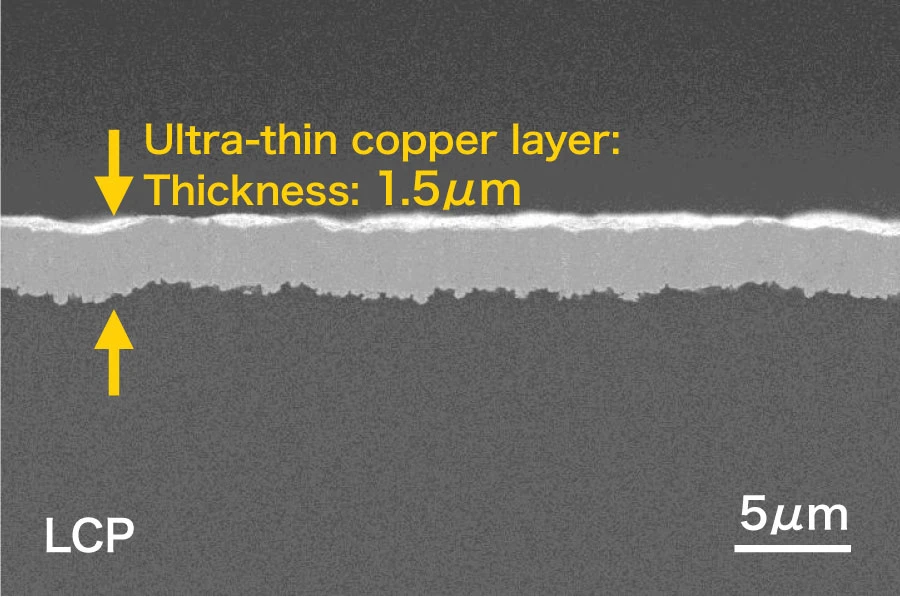

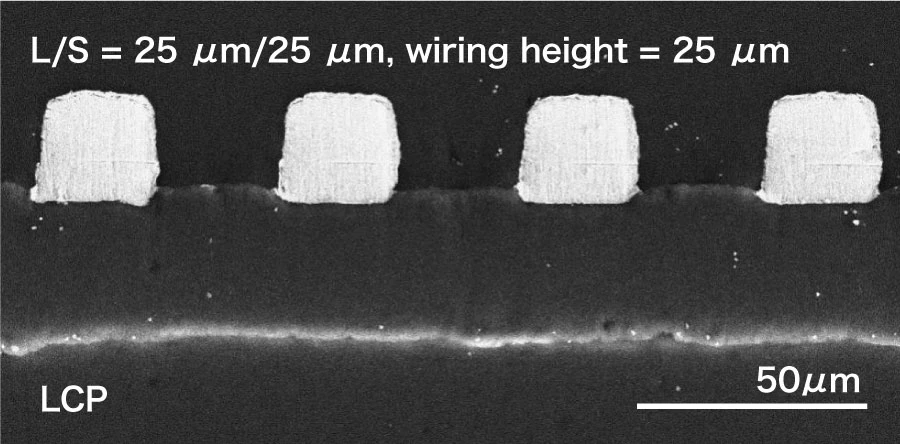

LCP base (Laminated ultra-thin copper foil with carrier/For fine wiring)

Laminated ultra-thin copper foil with carrier and LCP, FCCL applicable to MSAP

Carrier copper foil can be peeled off easily and evenly.

- Provided width: Max. 510 mm

- Format: Rolls, sheets

Composition

Ultra-thin copper layer lamination with low roughness

Conventional design Rz: 1.3 μm*

Low roughness design Rz: 0.9 μm*

Copper foil manufacturer’s nominal roughness

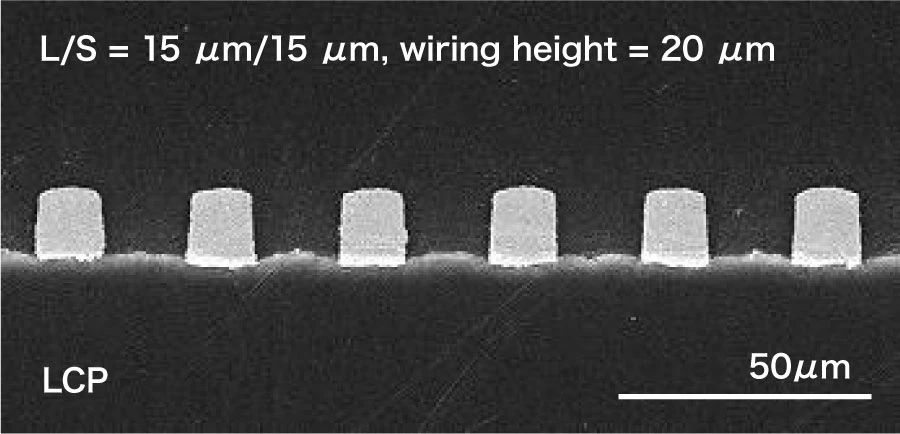

Achieves fine wiring using MSAP

General properties

| Item | Conditions | Copper foil with carrier FCCL |

|---|---|---|

| Conductor peel strength | 18 µm thickness after plating At room temperature JIS C 6481 | 1.0 N/mm |

| Cross section after peeling off carrier copper foil | room temperature | 0.03 N/mm |

| Dielectric dissipation factor | Open resonant Fabry–Perot method 28GHz | 0.002 |

| Relative dielectric constant | 3.3 | |

| Solder heat resistance | 288°C, 10 seconds | No abnormality |

The above data are representative values measured by our company, not guaranteed values

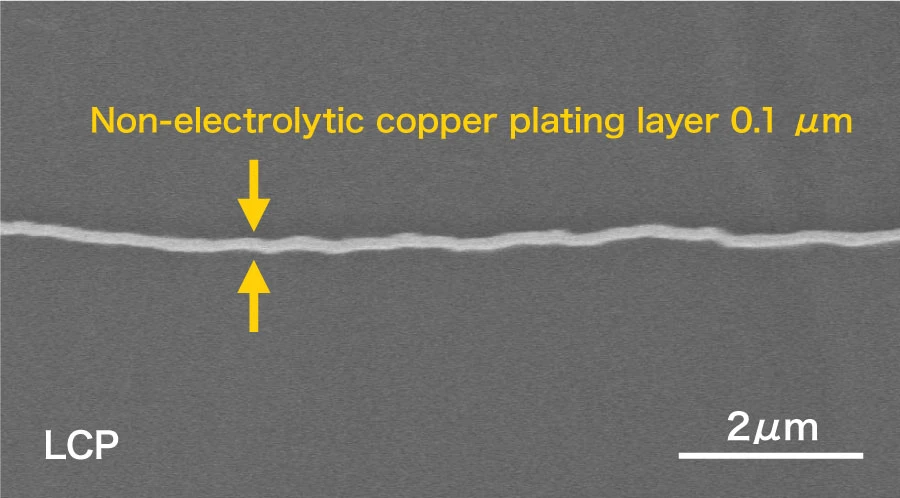

LCP base (Ultra-thin plating/For fine wiring)

Ultra-thin copper of 0.1 to 0.3 μm laminated on LCP by non-electrolytic plating

FCCL enables fine wiring processing and excels in high-frequency characteristics

FCCL enables fine wiring processing and excels in high-frequency characteristics

Composition

Excellent high-frequency characteristics achieved by interface smoothing

Achieves fine wiring using SAP

General properties

| Item | Conditions | Non-electrolytic copper plating (FCCL) |

|---|---|---|

| Conductor peel strength | 18 µm thickness after plating At room temperature | 0.7 N/mm |

| 18 µm thickness after plating After 168 hours at 150°C | 0.7 N/mm | |

| Dielectric dissipation factor | Open resonant Fabry–Perot method 28GHz | 0.002 |

| Relative dielectric constant | 3.3 | |

| Solder heat resistance | 260°C, 5 seconds | No abnormality |

The above data are representative values measured by our company, not guaranteed values